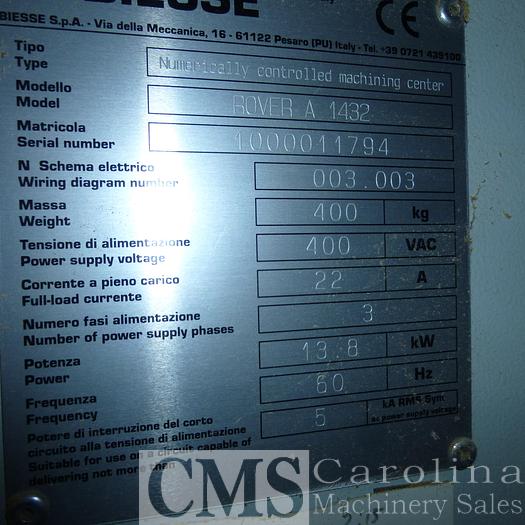

2016 Biesse Rover A 1432 Pod and Rail CNC Machining Center

Specifications

| Manufacturer | Biesse |

| Model | Rover A 1432 Pod and Rail CNC Machining Center |

| Year | 2016 |

| Stock Number | 011703 |

Description

Working Capacity:

"X axis 125.9" (3,200 mm), "Y" axis 52" (1,320 mm), "Z" axis stroke 13.7" (350 mm), max material thickness 9.6" (245 mm).

Positioning speed:"X" 262 FPM (80 MPM), "Y" Axis 196 FPM (60 MPM), "Z" axis 98 FPM (30 MPM)

AC Brushless Servo motors with digital drive and linear guides ensure high speeds with a smooth acceleration-and-deceleration.

Work Table:(6) Tube-less panel supports with lifting bars for heavy panels, (3) ATS vacuum pods per panel support

(6) Pneumatic back stops, (6) pneumatic front stops, (2) pneumatic side stops & (2) pneumatic central stops.

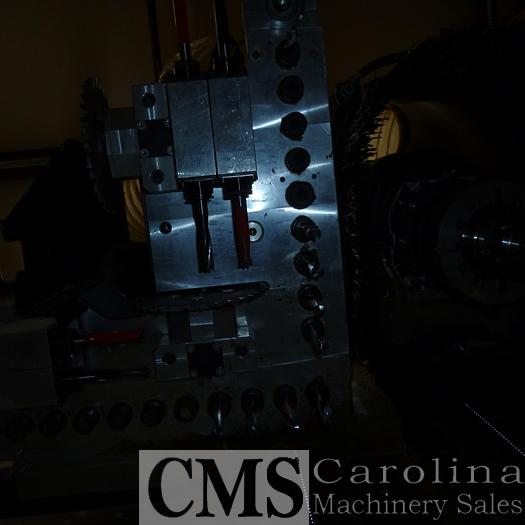

Boring Unit:4 HP (3 kW) motor with variable speed from 1,500 - 7,500 RPM; (18) "Quick Change" independent vertical spindles with (9) spindles in "X" axis & (9) spindles in "Y" axis;(8) horizontal boring spindles with (2+2) in "X" axis & (2+2) in "Y" axis;(1) 0° - 90° NC controlled "X"-"Y" Axis grooving saw for max 200 mm dia saw blade.

Machining:(1) 17 HP (13 kW) Liquid Cooled "HSD" electro-spindle router with HSK F63 adaptor, variable speed from 3,000 - 22,000 RPM;(26) Total ATC positions with (1) 8-Position ATC tool plate located on the machine head for "on the fly" ATC

Operator & Machine Control:PC Front End: Biesse "BH 600" + BiesseWORKS Advanced + WINDOWS "XP" operating system,15" TFT monitor, full standard keyboard & mouse, CD ROM disk drives,RS 232 & USB ports, Ethernet connection, specific function controls & and internet trouble shooting capabilities;Control cabinet with air conditioning & dust free environment.

"Biesse WORKS" is a multitask operating system, input/output modules, axes override, 4-axes interpolation, diagnostic graphics aid for programming, machine data & tool management.

Complete with:(1) 250 m³/Hr vacuum pump; automatic lubrication system; original documentation; hand held pendant; safety fences & mats; scrap conveyor;