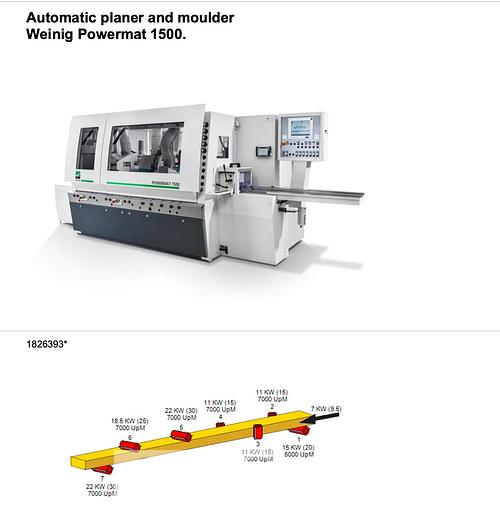

Weinig Powermat 1500 Moulder

Specifications

| Manufacturer | Weinig |

| Model | Powermat 1500 Moulder |

| Stock Number | 010960 |

Description

Weinig Powermat 1500 Moulder

7-head Machine

Manufacturer specs (to be confirmed):

Operating voltage (single) 460 Volt, 60 Cycles

Tool arrangement no. 013

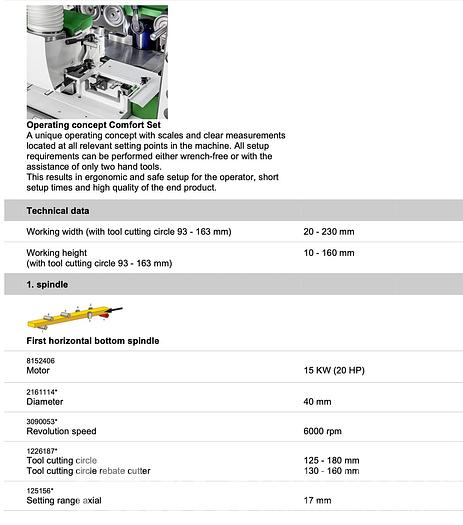

Working width 20 - 230 mm

FIRST BOTTOM - Motor 11 KW (15 HP) / 1 13/16" / 6000 rpm

Marathon coating for table insert

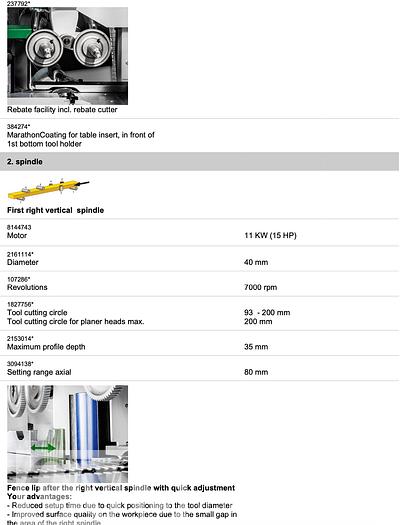

RIGHT VERT - Motor 11 KW (15 HP) / 7000 rpm

Diameter 40mm

Setting range axial 80mm

LEFT VERT - Motor 11 KW (15 HP) / 8000 rpm

Vario hood (2 axes)

Pressure shoe in front of left, incl. 2 lateral rollers, spring-mounted

Setting range of the feed rollers opposite left tool holder

Pressure roller from above, pivoting, spring loaded

Axial / Radial CNC-controlled adjustment

SECOND RIGHT - Motor 11KW (15 HP)

Fence lip before and after the right vertical spindle

Axial / Radial CNC-controlled adjustment

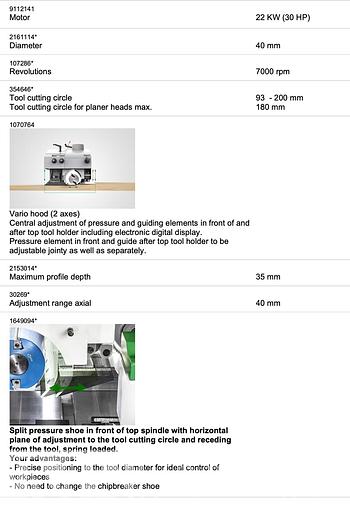

FIRST TOP SPINDLE-MOTOR 22 KW (30HP) - 7000 rpm

Vario Hood (2 axes)

Split pressure shoe in front of top spindle with

Axial / Radial CNC-controlled adjustment

SECOND TOP - Motor 18.5 KW (25HP)/ 7000 rpm

Split pressure shoe in front of top spindle

Axial / Radial CNC-controlled adjustment

Top spindle prepared cassette system.

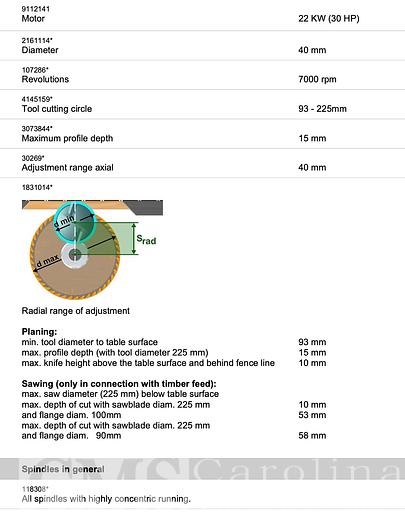

LAST BOTTOM - Motor 22 KW (30 HP) / 7000 rpm

Adjustment range axial & radial

FEED SYSTEM - Motor 7 KW (9.5 HP) / 5 - 40 m/min.

Feed roller in front of 1st bottom, pneumatic up-down

Electrical up-down adjustment of the feed bar

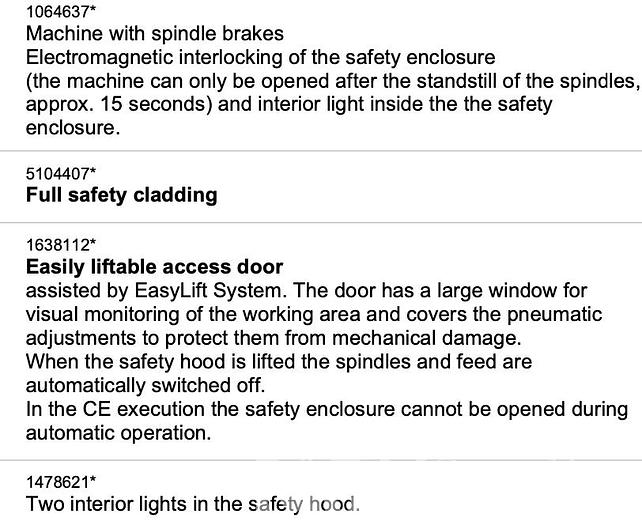

Two interior lights in the safety hood

Remote Lock out / Tag out

Lateral pressure roller at the infeed table, spring-mounted

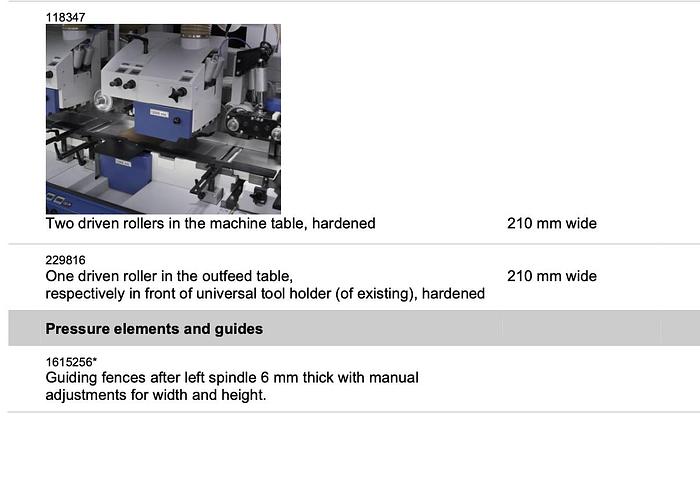

Guiding fence after the left vertical spindle 6 mm thick

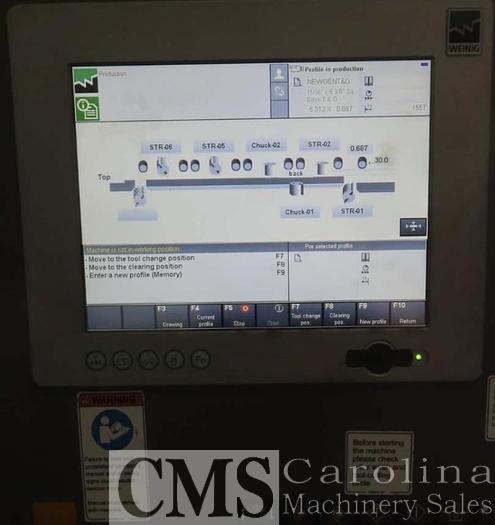

PowerCom Plus

Improved sound insulation

*

MACHINE CHANGE: 06.10.2019 - Please be aware that the VarioHood assembly on the

1st Top Spindle was moved to the 2nd Top Spindle position. The 2nd Top Standard

Hood was moved to the 1st Top Spindle Position. This move will impact the parts

relating to the Aspiration Hood, ChipBreaker and Pressure Shoe elements. Please

use caution when looking up replacement parts. This machine change was performed

by WUSA technicians