2022 Felder Format 4 Termpora 60.06L Edgebander

Specifications

| Manufacturer | Felder |

| Model | Format 4 Termpora 60.06L Edgebander |

| Year | 2022 |

| Serial Number | 220.01.021.22 |

| Stock Number | 010304 |

Description

Individually controlled valves.

Optimized maintenance unit with pressure sensor. Extra control air supply.

Tempora 60.06L pull out work piece support

Tempora 60.06L machine chassis The machine chassis of the tempora

60.06L edgebander is made from thick walled, electric welded construction steel

inside the chassis

high stability is achieved.

Operation tools tempora series

Machine nameplate tempora 60.06 L

Upper spring-loaded pressure bar tempora

60.06 and 60.06L Pressure bar made of welded torsion resistant steel construction. Using a hand crank, the height can be adjusted to the work piece between 8-60 mm Smooth, double-row staggered upper rollers distribute pressure evenly across the work piece. Workpiece

Chain feed for tempora 60.06 und 60.06L Feed speed 10 m/min

Drive motor 0.75KW (S6)

Minimum work piece width varies with work piece length, height and surface finish

Minimum work piece length 140 mm Segmented, rubber covered support pads with quick change system.

The minimum work piece width varies with work piece length, height and surface finish

Rotary tape coil D=750mm for tape coils 0.4-3 mm Rotary tape coil unit supported by

ball bearings. Rotary plate diameter 740mm.

Work piece feed and feed guide with manual adjustment.

The feeding support guide is suitable for sensitive surfaces

support surface 600mm.

Depth of cut

for the premilling unit can be manually set between 0-2mm on the feed guide.

Depth of cut is displayed via a digital counter.

Edge feed for coiled and strip edges in single feed

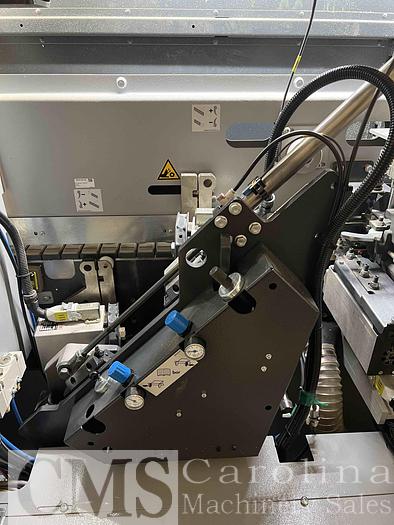

Pressure roller unit application pneumatically controlled 1 driven and 2 conical contact rollers manual adjustment can be read via the digital counter to read

Guillotine scissors for tape coil

with thickness between 0.4 to 3 mm

Premilling unit with immersion-controlled diamond milling cutters speed 12000 rpm 2x 1,1kW max. depth of cut 2 mm premilling

cutters with diamond cutters Z2+2 D-80 x 49 mm

Upper buffing unit

Lower buffing unit

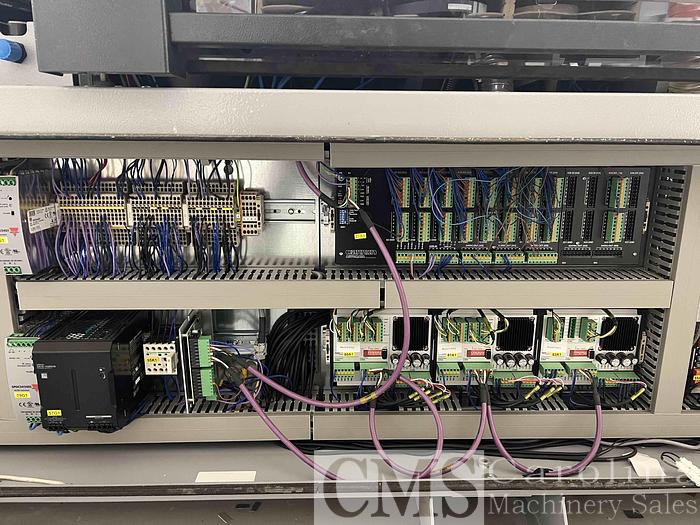

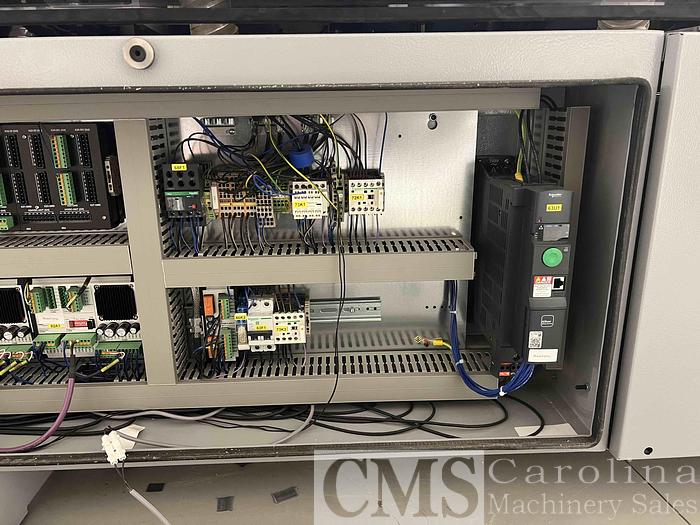

Fan for electrical control box

Pneumatic/mechanical infeed block Work piece distance control

A pneumatically controlled steel bolt prevents a work piece being inserted before the minimum work piece distance has been achieved. (Multiple copy rollers)

Strip magazine with a capacity of 120mm

Equipment bonus tempora 60.06EL

Spraying unit for cleaning agent

Spraying unit for releasing agent

motor controlled height adjustable pressure bar x-motion plus

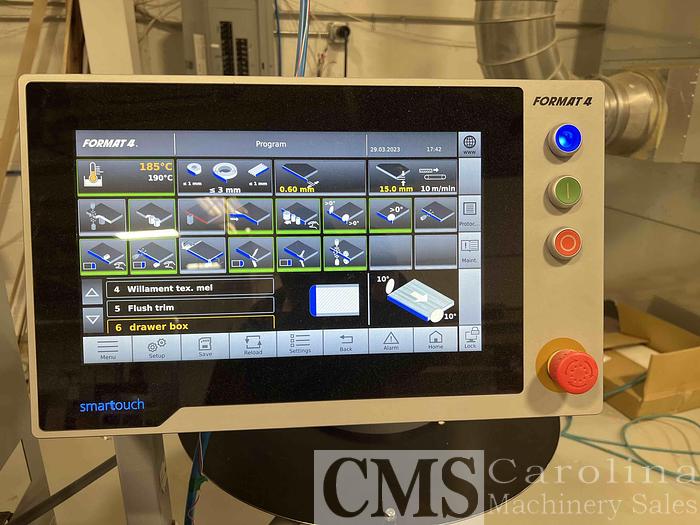

x-motion plus control with 15" smartouch

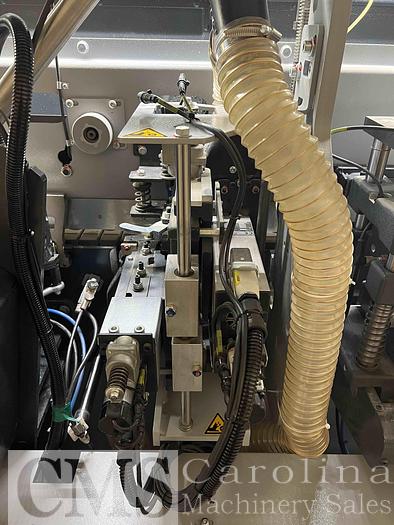

End trimming unit with two motors 0.35 kW (1 HP) 12000 rpm HW saw blades Z 24

D-100x20x3.2 mm pneumatically tiltable from 0°--10° for the processing of solid wood edges pressure points can occur on the edge material.

Upper multifunctional trimming unit x-motion plus using smartouch

flush and radius trimming unit position controlled 1 high frequency motor 0.75 kW (1 HP) 12000 rpm.

Lower multifunctional trimming unit x-motion plus using smartouch

flush and radius trimming unit position controlled 1 high frequency motor 0.75 kW (1 HP) 12000 rpm.

Upper radius scraping unit x-motion plus for processing of 2 and 3 mm plastic edges.

Lower radius scraping unit x-motion plus for processing of 2 and 3 mm plastic edges.

Corner processing unit with motor adjustment for post and Softforming profile Controlled profile trimming unit for the processing of the ends of the panel. Edge band thickness from 0.4-3mm. Workpiece

height 10-60mm. min. workpiece length 270mm Wood edges are possible depending on Restrictions on loose middle layers on post/softforming parts and extremely thin melamine/foil edges and surface materials

pneumatic controlled removal of the radius scraping unit

The control pneumatically moves the unit away from the working area.

Teflon coated glue unit for 1.5kg of EVA granulate with synchronised glue roller and quick change system as well as reversal of rotation. Suitable for the processing of of PUR adhesive with regard to the adhesive processing guidelines.

Lubrication agent spraying unit

Multiple copy rollers for the processing of work pieces with cabinet hinges

Upper glue scraping unit, pneumatically controlled for nesting

Lower glue scraping unit, pneumatically controlled for nesting

Electrics 3x208V 60Hz If the machine is equipped with a residual current

circuit-breaker (RCCB), then it must be a Type B, sensitive to universal current RCCB, suitable for frequency inverter operation with a release current of 300mA.