Black Brothers HPL Line with a 5' x 12' End Loading Cold Press

Specifications

| Manufacturer | Black Brothers |

| Model | HPL Line with a 5' x 12' End Loading Cold Press |

| Stock Number | 011832 |

Description

Station 1:

PNEUMATIC PANEL FEEDER

Panel Pusher feeds individual panels from side loaded (w/forklift) scissor lift into panel cleaner. Photo electric eye activates arm that pushes panel into panel cleaner.

Pusher arm: to feed panels into machine on demand

Switch: for remote mounting

Pass Line: 44"

24" Stroke with 4' of adjustment: to feed panels from 1/2 thick, up to 250 lbs, in lengths of 8', 10', or 12'

Controls on (Left or Right)

NEMA 12 Enclosure with main power disconnect switch and over-current protection: (230 or 460) Volt, 3 Phase, 60 Hertz, 24 VDC Control Circuits

Dual Limit Switch Arrangement: to control the Scissors Lift with "hand/auto" selector and a Barrier Guard to prevent double board feed.

Station 2:

SCISSORS LIFT 36" Vertical Travel foot operated raise/lower switch

48" X 120" Plain Deck with 6,000 Lbs Capacity

Internal Pump 460 Volt, 3 Phase, 60 Hertz, 24VDC Control Circuits

Pin Adjustable Edge Guides, mounted on SL

Anchor Clips for mounting

Transverse Conveyors with air brake to allow loading or unloading from side.

Station 3:

MIDWEST AUTOMATION PC160 Panel Cleaner with 63" Working width capacity, (2) spiral type cleaning brushes, 0" to 3" thickness opening, single end adjustment with roll opening (scale-type) indicator;

Variable feed speed 30 - 150 FPM with 1 HP - 1,725 RPM drive, (2) 6" dia. infeed and (2) 6" dia. outfeed rolls, variable brush speed with 3 HP motor. Equipped with: All guards, dust hoods, and magnetic starter.

Station 4:

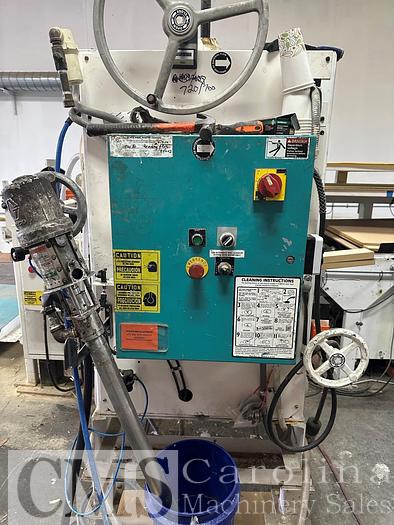

BLACK BROTHERS 775 TOP & BOTTOM ADHESIVE SPREADER, 68"

Application: To apply water base adhesive to top and bottom Particle board, plywood and MDF substrate

Upper Elevator: 0 to 4-1/2" Opening

Roll Opening Indicator: shows opening between rolls in .001 increments

Riser Base: 44" pass line height

Caster Arrangement: (4) plain rigid casters with guide track and lock

Coating Rolls: (2) 7-3/4" Maximum O.D., 60 Durometer - Neoprene/SPR, Grooved: 16 TPI

Doctor Rolls: (2) 7" Maximum O.D., 100 Durometer - Ebonite, Ground Smooth Single Hand-wheel Doctor Roll Adjustment with mechanical digital read-out. Electrical Interlocks on nip-guard(s)

NEMA 12 Enclosure with main power disconnect switch and over-current protection.

1-1/2 HP Single Speed with 3" reverse Lockout 88FPM

Pivoting In-Feed Table

Operating Hand-wheels & Controls: Parallel to direction of flow on right Motor On Left End

Operating Control Bars

Liquid Level Control: FIBER OPTIC

Machine Mounted Double Diaphragm Pump: l" Ports, Aluminum body with Neoprene diaphragm Feed Lines:

Automatic Roll Cleaning Arrangement

Station 5:

Hydraulic "Conveyo-Lift" with conveyor roller top; as board leaves the spreader, person on each corner guides the panel over the laminate and drop it onto the backer; operater applys overlay and the next substrate's backer from the laminate rack.

Foot pedal or indexing photoeye lower lift incrementally as each sheet is added; gravity roller conveyors on top of lift allow moving completed stack towards Cold Press infeed station.

Station 6:

LAMINATE INDEXING STATION 5' X 12' Application: To receive stock on center line from Glue Spreader, locate on Scissors Lift, and provide ready access to face and backer sheets to be laid up with glued panel stock - Load is then transferred to Air Pod Press for bonding

Unit is to handle panel sizes from 4' X 8' up to 5' X 12' - 1/2" and thicker

Operator side is on right

Pass Line Height - Infeed 44", Outfeed 17" - Finished Stack Height will be 26"

This Station includes: a Scissors Lift, a Shuttle to carry the front edge of the glued panel out over the Laminate, a Two Tiered Laminate Rack to hold stacks of facing and backer sheets, and a gravity roll conveyor to allow moving the stack from the scissors lift out of the indexing station

Scissors Lift is equipped with a roller conveyor with an air brake, to support and keep stock in position during lay-up with face and backer sheets, this process is repeated to build a stack up to 26" high - completed stack is then moved

to the next station - Edge guides are supplied for 4' & 5' stock

Shuttle Mechanism rides on side frames surrounding the Scissors Lift to carry the board out of the Glue Spreader, "Fingers" support the leading edge of the panel with a minimum amount of disturbance of the bottom glue line - the 1'Fingers" pivot down and release the glued stock to the bottom laminate

"V" Roll Support Arrangement with Slides - at infeed of Laminate Indexing Station supports the glued stock by the edges, the trailing end of the stock slides down to meet the bottom Laminate, width of Rolls is set manually to match panel

Laminate Rack has two tiers to support facing and backer sheets - It rides on a floor track and is operated by Air Cylinders to move out and over the lay-up area when the operator presses a switch - the rack remains out for a set time. then automatically returns to the starting position

Station 7:

Conveyor track section for staging of completed stack at infeed of press.

Station 8:

BLACK BROTHERS Power Pod Press; platen dimension: 62" x 147", end loading on 62" end, Variable daylight opening up to 45", single top platen zone, pneumatic top pressure via 5-1/2" stroke air pods, max. 50 PSI specific pressure, 2-track spring loaded feed chain in bottom platen for loading and unloading.