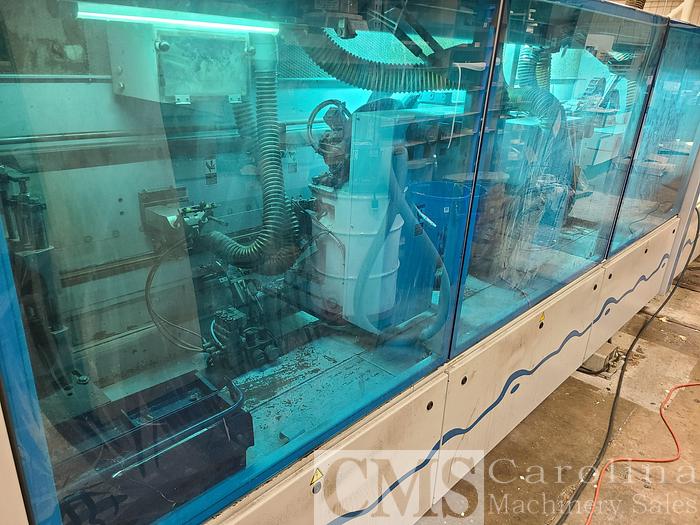

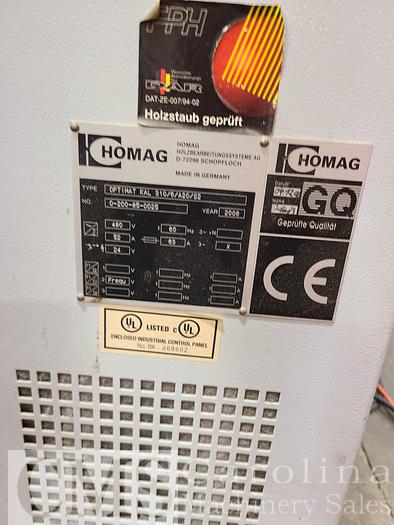

2006 Homag Optimat KAL 310 Edgebander

Specifications

| Manufacturer | Homag |

| Model | Optimat KAL 310 Edgebander |

| Year | 2006 |

| Stock Number | 009468 |

Description

Homag KAL 310 NOT INCLUDING THE RETURN

Year of MFG 2006

Control voltage 24 V

total connected load 50A

recommended fuse 28kW

nominal current pprox.. 39A

Dust extraction

air velocity (min.)

28 m/sec (91.84 ft/sec)

air volume 4090 m3/hr (2407 cfm)

static pressure 250 mm/ws (9.84”/ws)

CompressedAir

connection size ¾”

pressure required 7 bar (100 psi)

consumption / volume 705 sl/min (24.89 cfm)

Foundation requirements according to layout drawing

# 5-236-01-0360

Electrical equipment installed according to UL regulations. Voltage supplied must not fluctuate in excess of+/- 5% of its stated value. Voltage must be balanced phase-to-phase and phase-to-ground.

Note: The stated values are only applicable to the machine as specified.

Adding or deleting optional equipment may change service connection requirements.

In case ofvariations in technical specifications and capacities between the base machine and working units, the specifications and capacities given for the working units are to be considered correct.

Conditions offloor at installation site must adhere to foundation plan.

Adjustable lnfeed Fence

Homag Unit #0005

• with digital mechanical counter

Pre-Milling Unit

Homag Unit #3481

HOMAG KAL 525

• with two (2) motors 3 kW, 150 cycle, 9000 rpm

• for max. tool diameter of 125 mm (4-15/16")

• equipped with trimming column

• two (2) horizontal and cross slides with spindle adjustment

• electro-pneumatic horizontal jump movement of first motor

• two (2) dust extraction hoods

• air jet for panel cleaning

• with two (2) DIA jointing heads 125 x 35 x 30 mm(4-15/16" x 1-3/8" x 1-1/8"), DKN, z = 2 x 3

• max. workpiece thickness 30 mm (1-1/8")

• electronic frequency inverter for control of motor speed and braking

Noise Protection Stepped

Homag Unit #0424

• for pre-trimming unit

• allows for inlay of long strips

• centralized dust extraction port

Panel Pre-Heater

Homag Unit #2325

• quartz lamp for heating substrate edge before glue application

• for improved edge quality and optimum bonding

QA 34 Quick Melt Gluing Unit

Homag Unit #2123

• specially designed by Ho mag - the original innovator of the quick melt syste

• lower reservoir unit is designed with only seven (7) wearing parts,

which allows for ease of adjustment and reduces maintenance costs

• ideally suited for quick heat-up time and color changes

• one bolt secures lower unit to drive mechanism

• special coupling eliminates alignment of universal drive joint

• digitally displayed thermostat for both upper and lower unit, along with

heated glue roller allow for excellent control of temperature for optimum

bonding results

• individual adjustment for front and rear glue gates

• upper reservoir for glue granules

• glue roller diameter 34 mm (1-11/32")

• lower melting unit equipped with automatic control of glue level

Glue Roller Drive

Homag Unit #2141

• eliminates glue charring on glue roller

• lengthens pot life of glue during idle running time of machin• thermostatically controlled activation I nitiates glue roller drive when lower unit reaches melting temperature while feed track is stopped

Clamping Device for Glue Pot

Homag Unit #2143

• electro-pneumatic clamping of glue applicator at trailing edge of panel

• ensures consistent glue line

Glue Container Back-Off

Homag Unit #2145

• in case feed track stops

Multi-Purpose Magazine with Single Coil Horizontal Table

Homag Unit #2999

• capable of running coiled material, strips, and solid wood bands

• easily changed from one application to the next with the flip of a switch, conveniently located on the movable control pendant

• infeed angle 8°

• edge thickness 0.4 mm to 12 mm (0.016" to 1/2")

• edge height 12 mm to 65 mm (15/32" to 2-9/16")

• processing limits 900 mm2 (1.39 sq. in)

• min. edge length 260 mm (10-1/4")

Clipping Unit

Homag Unit #2445

• designed for today's popular use of thick coil PVC• for use with single-roll table magazine

• max. edge thickness 3.5 mm (0.14")

• max. edge height 65 mm (2-9/16")

• PVC processing limits 135 mm2 (0.19 sq in)

• veneer processing limits 100 mm2 (0.15 sq in)

• max. roll diameter 900 mm (35-7 /16")

Magazine Height Adjustment

Homag Unit# 2451

• with threaded spindle adjustment and digital readout

• adjustable +/- 5 mm(+/- 13/32")

Pressure Zone for Gluing Section Type C

Homag Unit #2507

• one (1) driven pressure roller 160 mm (6-5/16") diameter

• six (6) secondary pressure rollers 70 mm (2-3/4") diameter

• with pneumatic pressure control for straight edges

• centralized manual adjustment for edgeband thickness with digital mechanical counter

Snipping Unit HL 81

Homag Unit #3049

• for straight and chamfer snipping

• with two (2) motors, 0.8 kW, 200 cycle; 12,000 rpm

• max. edge thickness for straight snipping 20 mm (25/32")

• max. edge thickness for chamfer snipping 3 mm (1/8")

• chamfer angle of 30°

• edge cross section maximum of 900 mm2

• max. edge height 65 mm (2-9/16")

• feed speeds

- panel thickness up to 40 mm (1-9/16") - 25 m/min (82 ft/min)

- panel thickness up to 60 mm (2-3/8") - 20 m/min (66 ft/min)

- panel gap with 20 m/min (66 ft/min) 600 mm (23-58/8") min.

- with two (2) carbide tipped saws 120 mm (4-23/32") diameter; t = 30

• includes electronic frequency inverter with motor braking

Adjustment Chamfer, Straight

Homag Unit #3114

• for automatic re-setting from straight snipping to chamfer snipping

• manual motor adjustment required in case of modifications of edge thickness

Flush Trimming Unit 1.5 kW Optimat

Homag Unit# 3209

• with two (2) motors, positioned one above the other, 1.5 kW, 200 cycle, 12,000 rpm

• angle adjustment+/- 1 °

• with two (2) carbide tipped trimming cutters, 70 mm x 25 mm (2-3/4" x 31-32"), HSK 25, z = 4

• motors running against direction of feed

• height adjustment with top pressure beam

• two (2) TCT cutters 70 x 25 mm (2-3/4" x 31/32"), HSK 25, t = 4

• includes electronic frequency inverter for control of motor speed and braking

Pneumatic Adjustment of Flush Trimming Unit

Homag Unit #3251

• adjustment on two (2) positions:

o Position 1: rough trimming with projecting edge (approx 0.2 mm)

o Position 2: flush trimming unit without projecting edge

Set of TCT Flush Trimming Cutters "I" System

Homag Unit #3900

• in place of standard tool

• two (2) "I" TCT cutters 70 mm x 25 mm (2-3/4" x 31/32"), t=4, HSK 25 R

• with integrated chip collecting system

• up to 95 % of chips collected

• high processing quality due to improved extraction

• station dust extraction volume requirement reduced by as much as 50 %

Profile Trimming Unit FK 11

Homag Unit #3703

• for processing of protruding edge material at panel upper and lower edge as well as leading and trailing edges

• used in conjunction with snipping and rough trimming units

• two (2) motors, 0.4 kW, 200 cycle; 12,000 rpm

• chuck with quick change device for one (1) tool holder assembly

• manual tool change

• selection switch for top and bottom trimming only, or for trimming of top, bottom, leading and trailing edges

• separate tool holder assembly is required for each tool type and edge thickness

• profile end trimming of veneer and solid strips is limited

• electronic frequency inverter for control of motor speed and braking

• max. feed speed 20 m/min (65.6 ft/sec)

• min. panel length

o single-sided 240 mm (9-7 /16")

o double-sided 120 mm (4-23/32")

• min. panel distance 680 mm (26-25/32")

• panel thickness 12 mm to 60 mm (15/32" to 2-3/8")

• if panel thickness exceeds 40 mm (1-9/16"), the min. panel length increases to 230 mm (9-1/16")

• max. edge thickness 5 mm (3/16")

• without tool holder assembly or tools

Set of Change Heads "I" Automatically Adjustable/ FK

Homag Unit #3719

• two (2) processing units for installation on the profile trimming unit FK 11/13/21/23

• for automatic adjustment to varying edge thickness in case of chamfer

trimming and/or for automatic reset from chamfer trimming to radius trimming

• max edge thickness for chamfer with radius cutter:

o in case of r = 1.5 0.6 mm (0.02")

o in case of r = 2.0 0.8 mm (0.03")

o in case of r = 3.0 1.0 mm (0.04")

• chamfering angle approx 13 °

• designed for "I" tool with tool-integrated dust extraction

Set of Diamond Radius Cutters "I"

Homag Unit #3738

o for FK radius = 3 mm (1/8"), t = 4

o two (2) diamond cutters, basic diameter 62 mm (2-7 /16")

o edge thickness max. 3 mm (1/8")

Scraping Device Profile PN 10

Homag #4523

• tracing from top, bottom and laterally

• for edge buffing or rounding-off pre-trimmed PVC edges

• nozzles pneumatically controlled

• max. edge thickness 3 mm (1/8")

• unit top and bottom laterally adjustable by 30 mm (1-3/16")

• max. feed speed 24 m/min (79 ft/min)

• workpiece overhang 30 mm (1-3/16") (fixed)

• height adjustment with the top pressure beam

• suction box for PVC chips

Set of Quick-Change Cutter Heads for PN 1 O, R = 3 mm

Homag #4527

• two (2) quick-change cutter heads, radius 3 mm (1/8")

• including two (2) profile knives with reversible carbide tips

Pneumatic Adjustment for Profile Scraping Unit

Homag Unit #4522

• for electro-pneumatic positioning of unit into or out of processing area

Edge Buffing Unit Top and Bottom

Homag Unit #4400

• for smoothing of edges

• adjustable in inclination and height adjustment with top pressure

• workpiece thickness max. 60 mm (2-3/8")

• equipped with two (2) cloth buffing wheels

150 mm x 50 mm x 25 mm (5-29/32" x 1-31/32" x 31/32")

Noise Reduction Enclosure

Homag Unit #0415/0425

• for edge trimming section

• with individual dust extraction ports

• with viewing windows

• illuminated for ease of operator inspection

Electronic Control

• control with programmable memory (PLC)

• indication of all inputs and outputs by means of luminous diodes

• integrated line control for remote control of processing units

• multi-tasking control of PLC for precise unit operation

• part number in machine at choice

• compatible interface to all Homatic input systems

• recommended environmental temperature min. +5° C (41 ° F), max. +35° C (95° F)

Power Control PC22

Hardware

• Power Control PC22 with PLC-control (IEC6 l 131)

• modern control system based on industrial PC with 2 GHz CPU and 512 MByte RAM

• one ( 1) hard drive fixed

• one (1) hard drive for data back-up

• USB connection

• TFT flat screen with PC keyboard and mouse

• digital field bus system for inputs, outputs and connection of peripheral units

• prepared for network connection EtherNET, additional hardware and software required

• modem for remote diagnostics, invoicing according to tele-service contract, telephone line to be installed by customer